Copyright MHI © 2025 | All Rights Reserved

A loading dock is typically an elevated opening (or openings) in a building’s sidewall where shipments are sorted and staged for loading and unloading of trailers, shipping containers or rail cars. To make that area more accessible and safe during the movement of goods, loading dock equipment and attachments are used. Because the shipping and receiving process requires personnel to conduct loading and unloading processes, dock equipment is designed to ensure the safety of both the workers and the loads as they enter and exit the trailer. Typical equipment includes attachments that secure and bridge the gap between the vehicle and the dock, lighting to illuminate the inside of the trailer, building-to-vehicle communication systems and weather protection. What Is Dock Equipment? There are several types of dock equipment. These include: Security: To secure the trailer, shipping container or rail car to the dock face, or outside wall of the dock door area, and ensure that it does not roll or shift away, a variety of devices are employed. These include: Dock bumpers - Pieces of rubber located at the floor level of a dock opening to cushion the building from truck trailer impact. Chocks (also called wheel chocks - Triangular blocks of rubber, wood or metal placed in front of, between or behind truck wheels to prevent trailer movement. Trailer restraint - Mechanical or hydraulic devices attached to the dock face that connect to the trailer to prevent its movement. Trailer jack – A device used to support the vehicle end of an over-the-road trailer when the vehicle departs, leaving the trailer behind for extended loading or unloading. Gap bridging: To properly align the floor of the dock and the floor of the trailer, shipping container or railcar—or to close any space between the two—a variety of devices are used to adjust the elevation of the vehicle and bridge the gap. These include: Dock board or dock plate- A portable plate that can be placed manually or with a lift truck. Dock ramp or yard ramp – A portable metal ramp with curbs and wheels attached, pushed into position at the rear of a truck or side of a railcar to provide a bridge down to ground level for personnel or lift trucks to use in loading and unloading. The longer the ramp, the less steep the angle to be climbed. Dock leveler or edge-of-dock leveler - A manually, hydraulically air or electrically operated plate, located at the dock entrance, that can be raised and lowered to accommodate varying trailer floor heights. Dock lift – A fixed lift whose travel is generally 5 feet or less that is used to load/unload material from trucks and transfer it to dock or ground elevation. For loading and unloading trailers when no direct access to the building is available, a movable device can be used instead. These portable dock platforms use a scissor lift mechanism to lift the surface up to the level of the trailer. This allows personnel and handling equipment to ride up to the trailer and back down to ground level with loads. Hinged bridge - A hinged transition plate attached to the edge of the dock platform that unfolds to reach the truck bed. Conveyor – In certain facilities, trailers can be loaded or unloaded from a conveyor line in a fluid load process. Lighting: Lights are often used at the dock to both illuminate the work area, as well as to facilitate communication between personnel at the dock and a truck driver. Types include: Communication lights – Similar to traffic signals, these two- or three-light devices operate in pairs. The exterior light station signals to the truck driver when it is safe to dock the vehicle or depart from the dock. The interior light station notifies warehouse personnel that a vehicle is present at the dock face. Illumination lighting – Because dock areas are often utilized at night, dock lights are used to illuminate the work area, as well as to bring light into the trailer, shipping container or railcar to help personnel do their jobs safely. Weather protection: For dock areas that are exposed to the elements, a variety of devices are used to protect workers and surfaces from rain, snow, ice, heat and humidity. These include: Loading dock door – Similar to a residential garage door, these retractable doors can be made of panels or curtains to control ambient temperature and humidity inside the building. They can be opened manually or automatically when a trailer is secured to the dock face. Dock seal or weather seal - A rubber or canvas covered pad or drape that extends a few inches out from a dock face to seal the gap between the dock and the trailer’s entrance. Dock shelter - A cover that can be extended to protect the opening between the door of a rail car or truck and a warehouse from inclement weather. How Is Dock Equipment Used? Dock equipment is used at the point where a trailer, shipping container or railcar is loaded or unloaded. Shipping: At the dock faces where outbound shipments leave the facility Receiving: At the dock faces where inbound shipments arrive at a facility Yard: If a building has no elevated dock openings, or if all dock openings are occupied by other vehicles, loading and unloading can be accomplished in the yard What Are the Benefits? Dock equipment provides a variety of benefits: Communication: Lighting that indicates and directs truck drivers and warehouse personnel that it is safe to park, enter or exit a trailer Illumination: Lighting that extends into the trailer to help warehouse personnel as they load or unload contents Loading and unloading: Providing safe access by bridging the gap between the dock face and trailer, shipping container or railcar Safety: Preventing personnel or loads from tripping or falling through any gap between the trailer, shipping container or railcar and the dock face Security: Securing the transport vehicle to the building to prevent movement until the loading or unloading process is complete Weather protection: Protecting personnel and loads from inclement weather Where Is Dock Equipment Used? Dock equipment can be found in facilities in nearly every industry, including: Aerospace Appliance Automotive Beverage Chemicals Construction Consumer goods E-Commerce Food Hardware Hospital Manufacturing Materials processing Paper Pharmaceutical Plastics Retail Warehousing and distribution Read more about how Dock Equipment is used in different industries and applications. Case studies detailing the use of Dock Lifts can be found here. Learn More About Dock Equipment Loading Dock Equipment Manufacturers (LODEM) Industry Group Loading Dock Equipment Manufacturers (LODEM) Industry Group Members Dock Equipment Standards

ULMA Inoxtruck ULS, Inc. is hygienic (100% stainless steel) material handling equipment manufacturer focused on food&beverage and pharma industries. The design and materials used makes highly recommended equipment for those industries the environment is aggresive and there is no room for contamination . Breaking down our solution range, Inoxtruck has different solutions for pallet, tote, drum, buggies or other material transportation, elevation and tipping/unloading. We also offer solution for auxiliary equipment for packaging lines like roll, dies and other material handling.

For over 40 years, LTW has been synonymous with top-tier quality and precision. With more than 1,000 successful projects completed across 35+ countries, we’ve demonstrated consistent productivity. Always on time, always precise. Our turnkey automated pallet and large item storage and transport solutions offer maximum system availability, optimal space utilization, and secure storage for a wide range of products. Flexibility is one of our key strengths. While most components are manufactured by our parent company, Doppelmayr Holding SE, we focus entirely on meeting our customers' needs. Built to ropeway standards, our production quality ensures robust and durable intralogistics systems for clients worldwide.

Stock MHS engineers, designs and manufactures conveyor systems for transport and sortation. We specialize in conveyor systems and chutes, including non-ferrous and UHMW spiral chutes. Empowering high volume facilities to shift, sort, and ship more efficiently. Success Through Service We understand the value and importance of prompt and professional service in our industry. Our goal is to build lasting partnerships with clients in multiple industries and verticals.

New Age Industrial is a cutting-edge manufacturer of high-efficiency aluminum material handling equipment designed to optimize storage and transportation in warehouses, distribution centers, e-commerce fulfillment centers, and more. The lightweight, durable aluminum solutions from New Age Industrial offer exceptional versatility and longevity. Our innovative equipment is designed for manual picking environments or seamless integration with forklifts, man-up order pickers, robotics and AI-powered systems to deliver unparalleled efficiency, productivity, and flexibility. Our team of experts works closely with you to design customized solutions that perfectly meet your unique requirements. Our tailored solutions will help optimize operations, reduce costs, and enhance worker safety and ergonomics. We are committed to providing unique, innovative solutions and exceptional customer service. Discover how our extensive range of aluminum equipment solutions can optimize your operations!

MAVs deliver a lot of benefits, including higher efficiency, productivity, safety, and flexibility. To provide safe, efficient, and cost-effective movement of materials. To supplement or replace manually-operated material handling vehicles, such as forklifts, tuggers, and order pickers. For greater flexibility in material transport compared to fixed solutions, such as conveyors. In response to shortages in labor, allowing reassignment of employees to areas where they can add more value. To eliminate associate travel time during picking and order fulfillment.

Introduction to Conveyor and Sortation Systems: Conveyors and sortation systems allow for more efficient movement of materials within retail, wholesale, distribution, and manufacturing operations. Because they are engineered to transport and organize large volumes of materials rapidly through a process, conveyors and sortation equipment save labor expense and increase handling productivity.

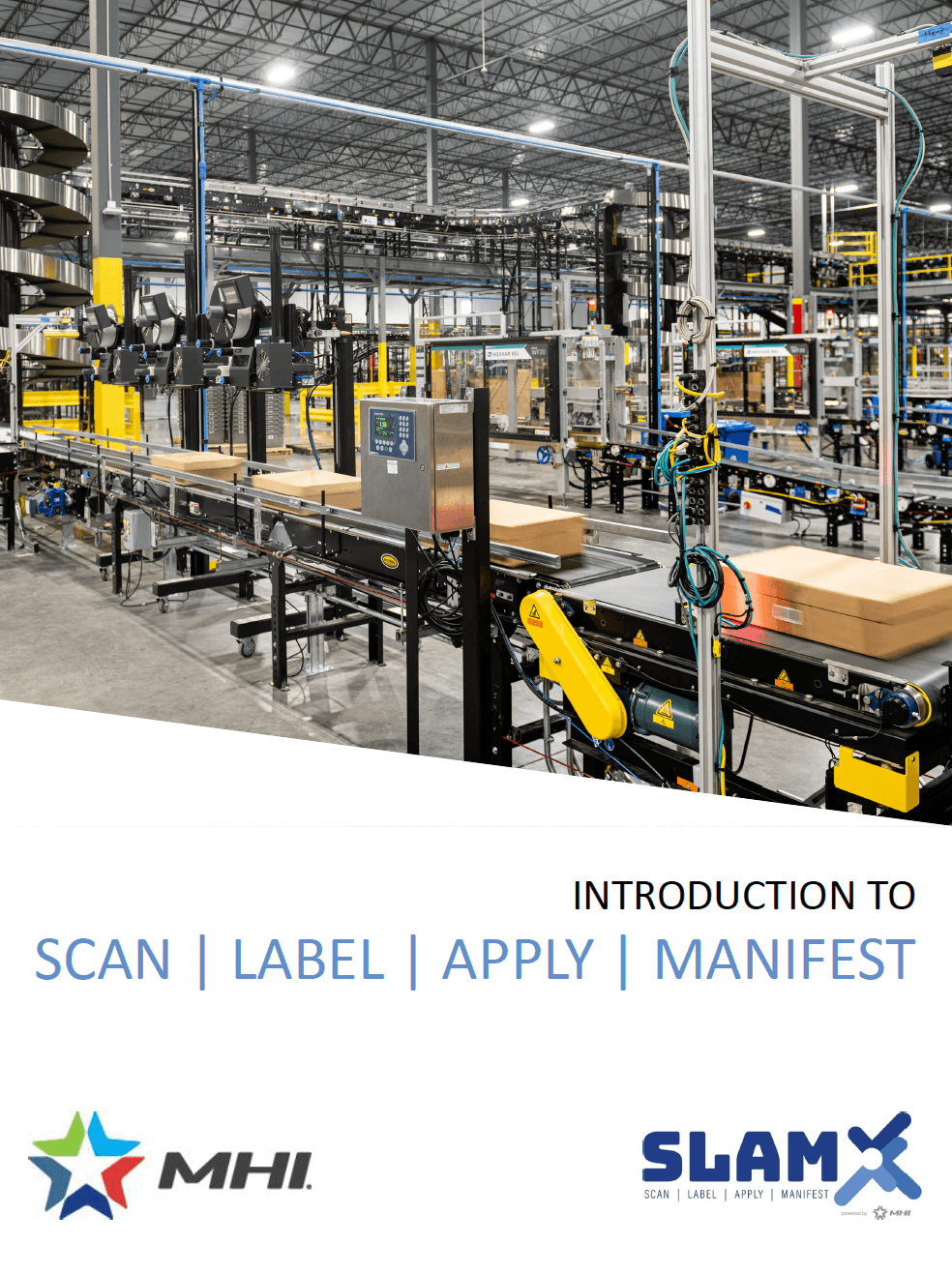

This document provides an introduction to SLAM (Scan, Label, Apply, Manifest), which is a critical element in "the last 100 feet" of every warehouse in the world.The document defines the following topics: Pack, Scan, Label & Apply, Manifest, and Transport & Sort. Within each topic area are best practice recommendations on how to apply SLAM principles to your application.This document was created by the SLAM Industry Group. For more information, please visit https://www.mhi.org/slam.

Manual transport aids (trucks and trolleys) are in widespread use throughout most industries, but their use does not always result in the anticipated reduction of workload or musculoskeletal stress. A survey of users has shown that many of the aids currently used are poorly designed or inappropriate for the tasks performed.

Bosch Rexroth is expanding its comprehensive VarioFlow conveyor system to include the new VarioFlow belt conveyor variant, which features a fine-meshed chain surface. It ensures the smooth transport of FMCG, pharmaceutical and healthcare products.The new VarioFlow belt conveyor is a stand-alone conveyor system for flexible CPG products, delicate products and diverse items. The modular belt chain has a very fine-meshed, almost closed and flat surface. This makes it suitable for the mass transport of unstable or bulk, film-packed products such as small sealed-edge bags. However, the VarioFlow belt conveyor can also be used to convey large or wide products, such as packs of paper towel or toilet paper. Products that are inherently stable can even protrude sideways in horizontal sections. Unlike conventional chain conveyor systems, VarioFlow modular belts are also suitable for the direct transport of deep-drawn plastic trays, which usually have a delicate contact surface.Customized basic modules – identical system componentsVarioFlow belt includes modular belts in standard widths of 406 and 608 mm. Scalable cross connectors make it possible for integrators to also implement customized belt widths with identical system components. The basic components of the modular belt conveyor system comprise the base unit for the drive, the return unit, the section profile as well as vertical and horizontal curves. These allow conveyor lengths of up to 30 m, layouts with curves on both sides and conveyor speeds of up to 40 m/min to be realized with one drive. In terms of accessories, VarioFlow plus and VarioFlow belt use identical system components such as product guides, leg sets and drive kits.Quick configuration and design with MTproMTpro, the free and intuitive software for planning assembly systems, supports users from selection and configuration through to ordering of Rexroth products. The Layout Designer enables even the most complex constructions and system layouts to be created in minimal time. An integrated evaluation function for the individual configuration eliminates the need for a third party to check the design and further reduces the engineering times.Quick and simple installation Smart solutions also reduce the time required to assemble the conveyor sections. For example, fewer sliding rails need to be installed compared to standard solutions on the market. The sliding rails are mounted from the side without the use of rivets, thereby eliminating the need to machine the running surface and ensuring the VarioFlow belt runs extremely smoothly and with little wear.About Bosch RexrothAs one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, around 33,800 associates generated sales revenue of 7.6 billion euros in 2023.To learn more, please visit www.boschrexroth-us.com.About BoschThe Bosch Group is a leading global supplier of technology and services. It employs roughly 429,000 associates worldwide (as of December 31, 2023). The company generated sales of 91.6 billion euros in 2023. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 90,000 associates in research and development, of which nearly 48,000 are software engineers.Additional information is available online at www.bosch.com, www.iot.bosch.com, www.bosch-press.com.ContactBosch Rexroth CorporationEden Estabrook(704) 942-4227Eden.estabrook@boschrexroth-us.com

Mitsubishi Electric has launched its latest FR-D800 series inverters, designed to deliver better performance, easy operation, and improved energy efficiency for a wide range of industrial applications. Compact and intuitive, the new series delivers powerful performance alongside features designed to make selection, installation, and operation simpler.With a focus on user-friendliness, the FR-D800 inverters feature a door-style surface cover and integrated wiring to make installation faster and easier. The FR-D800 is up to 37% smaller*1 than its equivalent predecessor, reducing enclosure size requirements, allowing for more flexible mounting, and reduced installation costs. A new USB Type-C interface lets users set parameters directly from a PC without powering up the inverter, streamlining both setup and maintenance.Parameters can be set without needing to power the inverters main circuit.The inverters can help save energy with advanced synchronous motor control, which reduces power consumption and cuts operating costs. Its high-efficiency motor drive and lower standby power consumption also contribute to a reduced carbon footprint, supporting more sustainable production practices."With the FR-D800 series, we wanted to create an inverter that both new and experienced users can use with confidence," said Shotaro Marumoto, Inverter Development Section Leader at Mitsubishi Electric. "We've made it straightforward while delivering the advanced performance businesses need to improve productivity, save energy, and meet their sustainability goals."The FR-D800 series is suitable for a wide range of applications, from conveyors and pumps to food processing equipment and textile machinery. Selected models*2 are also suitable for harsh, corrosive environments, thanks to circuit board protection meeting IEC 60721-3-3:1994 3C2/3S2 standards. Furthermore, FR-D800 inverters can control both induction and permanent magnet (PM) motors, eliminating the need for multiple inverters for different motor types. Built-in support for popular Ethernet protocols including CC-Link IE TSN, Modbus/TCP, and EtherNet/IP ensures seamless integration into existing industrial networks, enabling users to quickly integrate it into their digital manufacturing and smart production environments.The series also makes maintenance simpler. Its preventive maintenance functions include lifetime diagnostics for key components like capacitors and fans, helping operators spot potential issues early, especially when using the FR Configurator2 support software. Anomaly detection based on current patterns helps reduce the risk of unexpected downtime, and when a fault does occur, analysis functions solve the problem quickly."Energy efficiency, simplicity, and reliability are essential for modern automation applications and industry in general," added Marumoto. "The FR-D800 series shows Mitsubishi Electric's commitment to providing solutions that meet these needs while contributing to a greener future."The FR-D800 series will be available globally from March 2025, with models designed for different voltage requirements, including single-phase 100V, 200V, and three-phase 400V options.To learn more about FR-D800 series, please visit us.mitsubishielectric.com/fa/en/products/drv/inv/pmerit/fr-d/fr-d800/.Should you have further technical questions, our local expert Tom Henfling, Product Manager, VFDs for North America, may be contacted directly at Tom.Henfling@meau.com.About Mitsubishi Electric Automation, Inc.Headquartered in Vernon Hills, Ill., Mitsubishi Electric Automation, Inc. is a U.S. affiliate company of Mitsubishi Electric Corporation. It offers a broad product portfolio including programmable automation controllers (PAC), programmable logic controllers (PLC), human machine interfaces (HMI), variable frequency drives (VFD), servo amplifiers and motors, control software, computerized numerical controllers (CNC), motion controllers, robots, low-voltage power distribution products, and industrial sewing machines for the industrial and commercial sectors. Additional information about Mitsubishi Electric Automation is available at us.MitsubishiElectric.com/fa/en.About Mitsubishi Electric CorporationWith more than 100 years of experience in providing reliable, high-quality products, Mitsubishi Electric Corporation (TOKYO: 6503) is a recognized world leader in the manufacture, marketing and sales of electrical and electronic equipment used in information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, transportation and building equipment. Mitsubishi Electric enriches society with technology in the spirit of its “Changes for the Better.” The company recorded a revenue of 5,003.6 billion yen (U.S.$ 37,3 billion*) in the fiscal year ended March 31, 2023. For more information please visit https://www.MitsubishiElectric.com.*U.S. dollar amounts are translated from yen at the rate of ¥134=U.S.$1, the approximate rate on the Tokyo Foreign Exchange Market on March 31, 2022About Mitsubishi Electric Factory Automation Business GroupOffering a vast range of automation and processing technologies, including controllers, drive products, power distribution and control products, electrical discharge machines, laser processing machines, computerized numerical controllers, and industrial robots, Mitsubishi Electric helps bring higher productivity – and quality – to the factory floor. In addition, its extensive service networks around the globe provide direct communication and comprehensive support to customers. The global slogan “Automating the World” shows the company’s approach to leverage automation for the betterment of society, through the application of advanced technology, sharing know-how and supporting customers as a trusted partner.For more about the story behind “Automating the World” please visit: www.MitsubishiElectric.com/fa/about-us/automating-the-world.About e-F@ctorye-F@ctory is Mitsubishi Electric’s integrated concept to build reliable and flexible manufacturing systems that enable users to achieve many of their high speed, information driven manufacturing aspirations. Through its partner solution activity, the e-F@ctory Alliance, and its work with open network associations such as The CC-Link Partners Association (CLPA), users can build comprehensive solutions based on a wide ranging “best in class” principle.In summary, e-F@ctory and the e-F@ctory Alliance enable customers to achieve integrated manufacturing but still retain the ability to choose the most optimal suppliers and solutions.*e-F@ctory, iQ Platform are trademarks of Mitsubishi Electric Corporation in Japan and other countries.*Other names and brands may be claimed as the property of others.*All other trademarks are acknowledgedContactPam SummersMarketing Communications Manager+1 (847) 478-2415Pam.Summers@meau.com

New size 280 compact modules – available with either ball screw or toothed belt drive – can transfer payloads up to 250 kg at speeds up to 5 m/sIn response to a growing need to transfer heavier items faster and more efficiently throughout manufacturing processes and a rapidly changing e-commerce landscape in supply chain operations, Bosch Rexroth has expanded its extensive compact modules portfolio. The new size, 280, can support items up to 250 kg, which makes it ideal for transferring battery modules, machine tools, furniture, palletizing gantries, robotic transfer units, and other larger items."Today’s manufacturers and warehouse operators are constantly searching for solutions to help them meet diverse consumer needs, including with their heaviest items,“ said Sean Barunas, Sales Product Manager, Bosch Rexroth. "These modules are engineered to meet those requirements and open new possibilities for Cartesian robot solutions."Compared to the largest version to date - the 200 - performance (more weight with the same dynamics) with the 280 increases by more than 50 percent. Payloads of up to 250 kg can be moved over a length of 5,500 mm. The high acceleration of up to 5 g and a maximum speed of 5 m/s are suited for short cycle times while maintaining high degrees of precision. As a configurable component, the modules can shorten the engineering of single axes, multi-axis, and Cartesian robots. The modules can be paired with automation packages that include a motor, drive, and controls, which speed up commissioning and make operating easier.Additional applications for the 280 module within manufacturing and warehouse operations lie in pick-and-place processes and transporting robots or cobots from one point in the line to another. The increased load capacity allows the module to withstand more than 4x the cantilevered forces as the 200 model.For more information on Bosch Rexroth’s complete line of compact module solutions, please visit boschrexroth-us.com.About Bosch RexrothAs one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, around 33,800 associates generated sales revenue of 7.6 billion euros in 2023. To learn more, please visit www.boschrexroth-us.com.About BoschThe Bosch Group is a leading global supplier of technology and services. It employs roughly 429,000 associates worldwide (as of December 31, 2023). The company generated sales of 91.6 billion euros in 2023. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 90,000 associates in research and development, of which nearly 48,000 are software engineers. Additional information is available online at www.bosch.com, www.iot.bosch.com, www.bosch-press.com.Contact Bosch Rexroth CorporationEden Estabrook(704) 942-4227Eden.estabrook@boschrexroth-us.com

Datalogic expands its ever-growing mobile computing portfolio with the new Memor™ K20-25, a compact, keypad-based mobile computer engineered to maximize efficiency in many operational environments. Combining the versatility of a smartphone with the tactile benefits of a physical keyboard, the Memor K20-25 redefines value, performance, and productivity for mobile workers across industries. It’s the ultimate data capture solution—pocket-sized, powerful, and purpose-built!Bologna, Italy – July 1st, 2025 – Datalogic, a global leader in automatic data capture and industrial automation markets, proudly announces the launch of the new Memor™ K20-25, the next-generation key-based mobile computer designed for businesses that demand speed, precision, and flexibility from their data capture tools. The Memor K20-25 is set to redefine industry expectations by addressing the diverse needs of both touchscreen and keypad applications, making it suitable for organizations of all sizes across different verticals, regardless of budget constraints.Designed to streamline operations across retail, healthcare, hospitality, transportation & logistics, and light manufacturing, the Memor K20-25 maximizes productivity through its perfect balance of portability and durability. Workers can confidently scan any barcode - even damaged or complex ones, including GS1 Digital Link formats – with exceptional speed and accuracy thanks to Datalogic’s powerful Megapixel Halogen™ DE2102-HP scan engine, reducing delays and minimizing errors that impact customer satisfaction and operational efficiency.Frontline workers can input data quickly and accurately in any lighting condition – even low light - thanks to the device’s clear 4-inch display and illuminated 24-key physical keypad, designed for comfortable extended use. With Android™ 13 OS (upgradeable to Android 15) and Google Mobile Services (GMS), businesses can protect their investment while ensuring seamless usage of their software applications across different devices and maintaining enterprise-grade security.Built to keep workers productive throughout their entire shift, the Memor K20-25 eliminates downtime as it features a 4,850 mAh battery that supports up to 10 hours of continuous work. Its rugged housing survives inevitable drops (from up to 1.5 meters) and harsh conditions of daily fieldwork. Options for Wi-Fi only or Wi-Fi/4G connectivity provide flexibility for both indoor and remote operations. The high-quality 13MP rear camera further enhances proof-of-delivery processes and documentation tasks, reducing manual paperwork and accelerating customer services.Datalogic’s Memor K20-25 sets the new standard for mobile computing versatility, uniquely combining touchscreen convenience and keypad efficiency, offering unmatched value and reliability for growing businesses. With the full support of Datalogic Mobility Suite and its Android SDK, customers can now unlock our scanner’s full potential, making it the definitive choice for organizations seeking one device that can evolve with their operations and deliver maximum return on investment.The Memor K20-25: Where Versatility Meets Productivity.For more information, visit www.datalogic.com.About Datalogic GroupA global technology leader in the automatic data capture and industrial automation markets since 1972, specializes in the design and production of barcode readers, mobile computers, sensors for detection, measurement and safety, machine vision and laser marking systems. These products and solutions enhance efficiency and quality across the entire value chain, in industries such as retail, manufacturing, transportation and logistics, and healthcare.Trusted by major global players in its four target sectors, Datalogic is recognized for its customer focus and commitment to quality, upheld by the Group for over 50 years.Today, Datalogic Group, headquartered in Bologna (Italy), employs approximately 2,700 staff worldwide, distributed in 27 countries, with 10 manufacturing and repair facilities in the U.S.A., Hungary, Slovakia, Italy, China, and Vietnam, 10 Research & Development centers and 3 DL Labs in Italy, U.S.A., Vietnam, and Czech Republic. In 2024, Datalogic Group recorded sales of € 493.8 million and invested € 65.9 million in R&D. Datalogic S.p.A. has been listed in the Euronext STAR Milan segment of the Italian Stock Exchange since 2001 as DAL.MI. Visit www.datalogic.com.Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U. Other trademarks belong to their respective owners.Contactwww.datalogic.com

This is a paid advertisement.In the high-stakes environment of automotive manufacturing, Valeo needed to accelerate material flow—without slowing down operations. Instead of a disruptive overhaul, they partnered with Slip Robotics to deploy autonomous, loading/unloading SlipBots that integrated seamlessly into existing workflows. The results? 6X faster loading and unloading, reduced transportation waste, and zero forklifts inside trailers—boosting safety and efficiency across the board. Valeo’s transformation proves that with the right technology, B2B operations teams can unlock serious gains in speed, safety, and savings—without the headache of complex implementation.

An integrated supply chain can result in disruptions from various factors such as natural disasters, transportation failures, labor strikes, geopolitical conflicts, or a single supplier/manufacturing failure.

An integrated supply chain can result in disruptions from various factors such as natural disasters, transportation failures, labor strikes, geopolitical conflicts, or a single supplier/manufacturing failure.

Transportation and logistics needs have grown with the increasing demands on the supply chain. Not only does a TMS help people keep track of goods, but automating parts of it is essential to keep up with innovations across the industry.

Price: $25.00This standard applies to underhung cranes whose end trucks operate on the lower flange of a patented-track runway section; and to carriers (trolleys) operating on single-track patented-track monorail systems, including all curves, switches, transfer devices, lift and drop sections, and associated equipment. Systems used for transporting personnel require special considerations and are not included in this standard. This standard does not apply to enclosed-track runway sections, enclosed-track monorail systems, structural-shape runway section, or structural-shape monorail systems. Refer to ANSI MH27.2 2025, Enclosed Rack Underhung Cranes and Monorail Systems for enclosed-track runway sections and enclosed-track monorail systems.Hoist(s) or carrier(s) may be supplied by the crane manufacturer, crane distributor, crane installer, or by the user. In either case, the applicable portions of ASME/ANSI B30.16, Overhead Hoists (Underhung); ASME B30.11, Monorails and Underhung Cranes and appropriate ASME HST Performance Standards apply to the hoist(s) and carrier(s). If the hoist(s) or carrier(s) are supplied by the user, the crane builder shall be provided with certified dimensional drawings with all required data including wiring diagrams, carrier collector locations and weights.This standard includes considerations for cranes and monorail equipment only. It does not include considerations or specifications for the design of the building, the design of supporting structure, electrical power supply, or erection.This standard applies to systems operating in normal ambient temperatures and atmospheric conditions; any other conditions require special consideration.

Price: $25.00This standard applies to underhung cranes whose end trucks operate on the internal flange of a runway using enclosed track section; and to trolleys (carriers) operating on single-track monorail systems, including all curves, switches, transfer devices, lift and drop sections, and associated equipment. Systems used for transporting personnel require special considerations and are not included in these specifications. This standard does not apply to underhung cranes whose end trucks operate on the lower flange of a patented-track runway section. Refer to ANSI MH27.1-2025, Patented Track Underhung Cranes and Monorail Systems for patented-track runway sections and patented-track monorail systems.Hoist(s) or carrier(s) may be supplied by the crane manufacturer, crane distributor, crane installer, or by the user. In either case, the applicable portions of ASME/ANSI B30.16, Overhead Hoists (Underhung); ASME B30.17, Cranes and Monorails (With Underhung Trolley or Bridge) and appropriate ASME HST Performance Standards apply to the hoist(s) or carrier(s). If the hoist(s) or carrier(s) are supplied by the user, the crane builder shall be provided with certified dimensional drawings with all required data including wiring diagrams, carrier collector locations and weights.This standard includes considerations for cranes and monorail equipment only. It does not include considerations or specifications for the design of the building, the design of supporting structure, electrical power supply, or erection.This standard applies to systems operating in normal ambient temperatures and atmospheric conditions; any other conditions require special consideration.

Click Here to Read More

Click Here to Read More

Guest blog from MHI Member Company New Age Ind...

As the speed of manufacturing, transportation, and supply chain operations continues to accelerate...

DENSO had two primary objectives in mind, to overcome labor shortages and improve warehouse operation safety for associates driving vehicles inside the facility.Together, DENSO, Bastian Solutions and Toyota Material Handling integrated five AGVs into their Maryville, Tennessee warehouse. By automating the transport of product pallets from receiving to production lines, DENSO can better leverage their human labor force for improved

There are severe labor shortages within the agricultural industry, especially when it comes to seasonal workers. These workers are needed to perform manual, physically strenuous jobs, like transporting potted plants around an outside space, which is a necessity for horticulture. The plants need to be spaced out and periodically moved to different locations depending on their stage in the life cycle

RTI’s VanishPoint products have a unique retractable syringe and are used to administer the Moderna and Pfizer vaccines. RTI was previously using monorails over their injection molding machines and forklifts on the ground for transportation, but they found this to be inefficient because the fixed monorail beams did not offer any side-to-side movement capability of the trolley. OMi Crane Systems, Inc. recommended the installation of three cranes from R&M Materials Handling, Inc. OMi supplied RTI with 3-ton capacity, top-running single girder bridge cranes that feature an electric chain hoist and motorized trolley.

TUCKER GmbH, headquartered in Giessen, was founded in 1959 and is part of the Black & Decker Corporation. Over 1,100 employees develop and produce innovative, high-quality fastening and joining technology for distribution around the globe. The manual transport of small parts from the warehouse was automated using KNAPP’s Open Shuttles – autonomous mobile robots. The Open Shuttles move on the shared travel paths and supply two workstations near the dispatch sorters with small parts. While on the move, they have to dodge obstacles such as other transport vehicles (forklift trucks, pallet trucks, etc.), persons in the warehouse and any pallets that have been left in the way.

In this podcast Karl Manrodt, professor of logistics and transportation at Georgia College, discusses ESG findings within the Warehousing Education and Research Council’s DC Measures Report and addresses the many challenges the supply chain faces with ESG efforts. Sharing and leveraging data may be the key to success.

Sponsored Content: Join Bastian Solutions' General Manager of Autonomous Vehicles Michael Marcum, as he discusses the future of AGVs in the material handling industry. During the discussion he speaks to how Bastian has seen AGVs support customer objectives by safely and consistently transporting products and materials in manufacturing and distribution operations. He also discusses how automated and autonomous vehicle systems are a cost-effective solution that increase efficiency, improve working conditions, and easily scale to match customer growth.

Click here to view the seminar

An integrated supply chain can result in disruptions from various factors such as natural disasters, transportation failures, labor strikes, geopolitical conflicts, or a single supplier/manufacturing failure.

Wheeled devices, generally made from plastic and/or metal, utilized to move items within a warehouse, distribution center or manufacturing facility. Carts can be equipped with drawers, bins, trays or flat surfaces to secure items for transport and storage. Carts utilize casters as well as pneumatic and semi-pneumatic wheels. See also Trays .

A form of powered conveyor used to transport heavy unit loads such as pallets and industrial containers. These conveyors can be single or double chain strand in configuration. This chain is not only the driving force but it is also the part which comes in direct contact with the load and provides friction which pulls the load forward. In some cases, free rollers on either side of or between the chain provide additional support to the load. Short sections of double strand chain conveyors are a common means of transferring loads at right angle to/from another straight section of roller conveyor.

Generally constructed of plastic, metal or wood, a pallet is a piece of transportation/movement equipment utilized in the movement of unit loads. Usually "fork-liftable" in that it is designed to accept forks between the top and bottom platforms of the unit. A portable, horizontal, rigid platform used as a base for assembling, storing, stacking, handling and transporting goods as a unit load, often equipped with a superstructure.

Wheeled vehicle used in the plant or distribution center, in the dock area (and in some cases also in the yard or on construction sites, to pick up, transport and deposit single loads. May be powered manually, by gasoline, propane or electrically.

This free full color downloadable booklet was developed by EASE in partnership with CAL/OSHA, NIOSH and CNA; this booklet will help all companies, particularly small to mid-sized companies, recognize high-risk manual material handling work tasks and choose effective options for reducing their physical demands including: 1) Eliminating lifting from the floor and using simple transport devices like carts or dollies, 2) Using lift-assist devices like scissors lift tables or load levelers, 3) Using more sophisticated equipment like powered stackers, hoists, cranes, or vacuum assist devices, 4) Guiding your choice of equipment by analyzing and redesigning work stations and workflow. View Interactive version .